Biaxial Testing for Fabrics

Architectural fabrics are used in high profile tensile structures worldwide, and accurately determining the fabric’s material properties is vital to achieve safe, efficient designs. The understanding of the mechanical properties of architectural fabrics plays a fundamental role in the overall engineering of a structure and this is best achieved through biaxial testing.

Biaxial testing allows the fabric’s response to be investigated under different load conditions in warp and weft directions simultaneously in response to the stress conditions. This information assists in analysing the initial behaviour at installation, prestress behaviour and long-term behaviour. This information provides the overall dynamic behaviour of a fabric. Such information is fundamental in determining the compensation of the panels of fabric, together with the erection and pre-tensioning processes. Ultimately a biaxially stable fabric assists in the design and fabrication of the membrane and will provide more even force distribution and pre-stress loads, resulting in easier installation and a more efficient structure, which better maintains its shape and performance over its service life. There are currently limited standards for biaxial testing of fabrics used in building fabric structures.

International standards for architectural fabrics have historically focussed on the uniaxial behaviour or performance in a single direction of a fabric. This is commonly examined using tensile testing equipment, which concentrates on comparing the tensile strength, breaking strength and maximum elongation in one direction. This data alone cannot be used to produce a complex loading analysis as fabric forces during a loading event effect both the warp and weft directions simultaneously. When examining the material beyond its elastic properties, uniaxial results become unusable. An adequate analysis of the fabric’s bi-directional mechanical characteristics under all types of loads is only possible through a biaxial test.

A biaxial rig is a testing machine able to pull both warp and weft directions simultaneously. The test rig should hold the sample and allow elongation in both directions to create a central area, characterised by a uniform stress state, to measure the elongation in the warp and weft directions.

There are currently no Australian, European or American standards for the biaxial testing of fabrics. The only relevant standard that does exist is Japanese code MSAJ M-02-1995, which is often regarded as a guide and starting point when testing fabrics. The specific test method can differ between laboratories; therefore, it is difficult to compare test reports unless fabrics have been tested in the same laboratory under the same conditions.

When designing a light weight tension membrane structure, a fabric that exhibits similar structural properties in both warp and weft directions has the advantages of;

- A more even distribution of forces into supporting structures,

- More equal prestress loads in both Warp and Weft directions resulting in easier patterning and installation,

- A better sharing of loads between Warp and Weft fibres resulting in less elongation of fibres over time and thus a better ability for the sail to retain its original design shape and avoid the fabric sagging.

A dimensionally stable fabric will extend the service life of a structure. If the fibres in the fabric have elongated excessively it will cause the fabric to sag and billow in the wind. This can result in a shade structure that no longer performs or appears at a visually acceptable level, therefore requiring maintenance or replacement. Furthermore, billowing can result in excessive stress on the fabric, the structure and connection points, increasing the possibility of a failure.

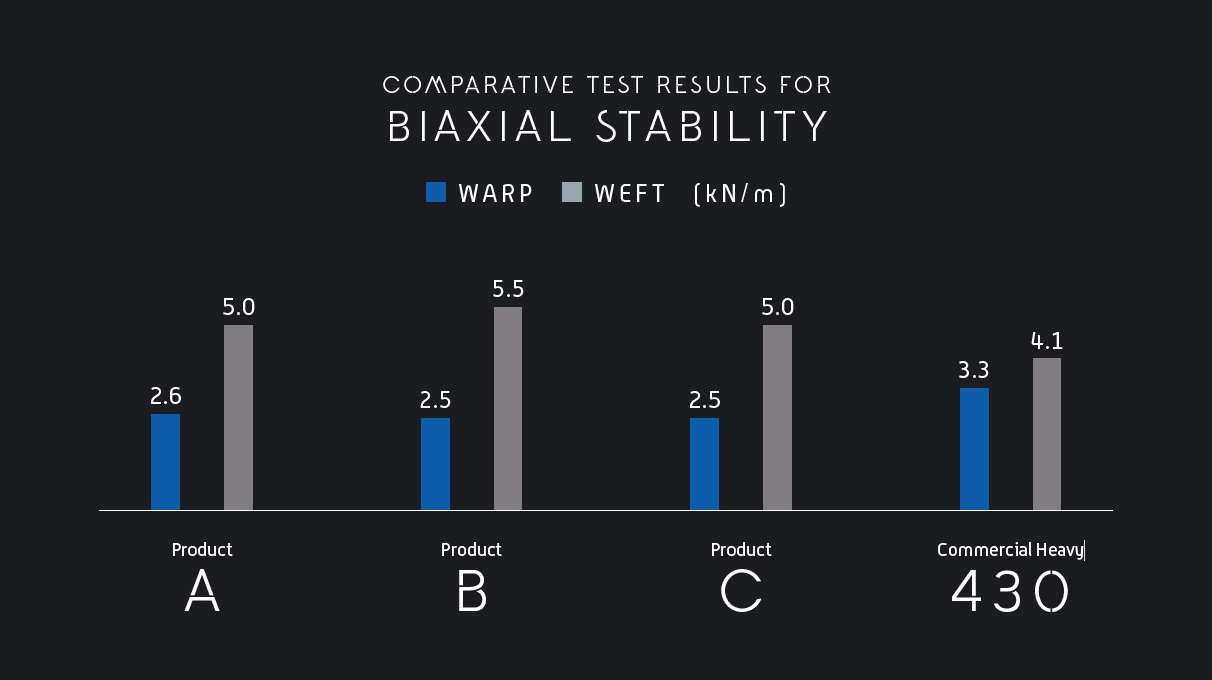

The key to avoiding unnecessary maintenance and replacement of the membrane component of a structure is selecting a fabric with superior biaxial stability. Commercial Heavy 430 featuring GALE Pacific’s patented intertwining knit pattern, designed to extend the service life and life span of light weight tension membrane structures. GALE Pacific are committed to the development of fabrics that have superior dimensional stable characteristics when compared to alternatives.

_LR_1_242_164_50_s_c1.jpg)